Stop wasting your budget, get better results from PCD dies

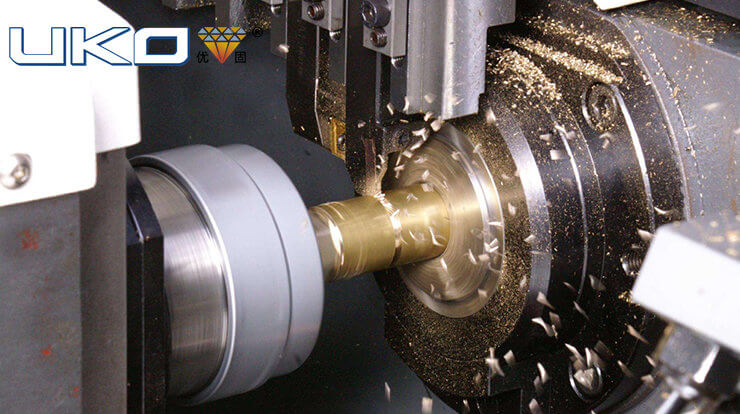

The wire drawing die refers to the tool that forces the metal to pass through the die under the action of external force during the metal pressure processing, the metal cross-sectional area is compressed, and the required cross-sectional area shape and size are obtained. baike.baidu Polycrystalline diamond (PCD) is a synthetic material invented by two […]

Stop wasting your budget, get better results from PCD dies Read More »