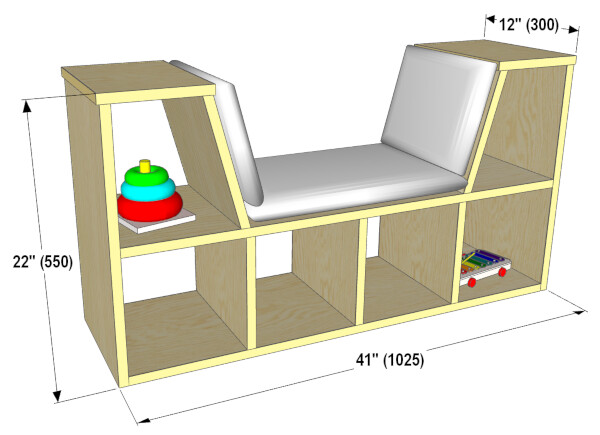

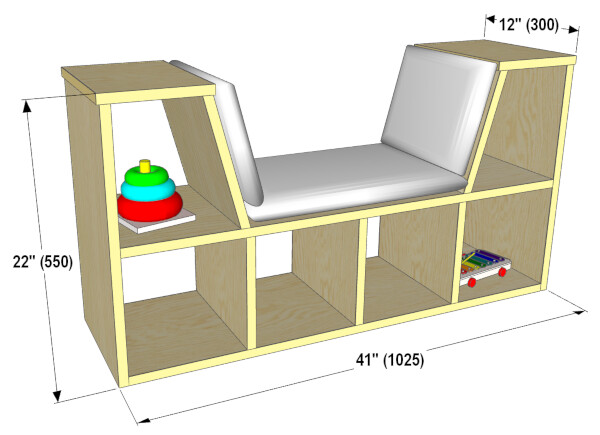

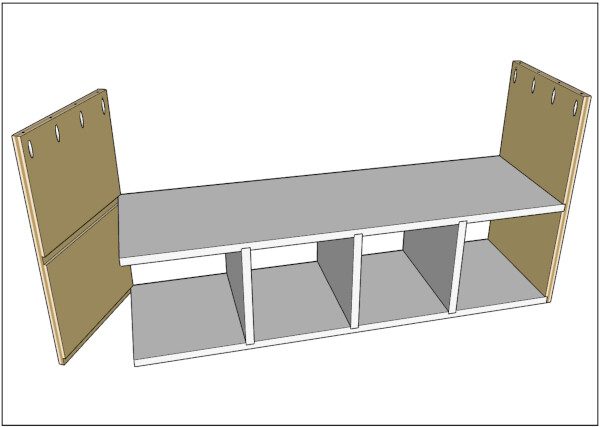

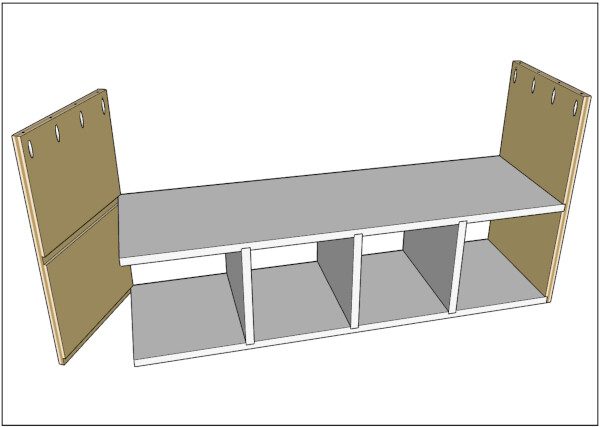

This toy shelf / book case / seat is sized for a kid. It’s made with 3/4″ plywood, joined with dado, rabbet, and pocket hole joints.

A single full sheet of plywood is plenty for this project. If you prefer to work with half sheets, you’ll need 2.

Plywood edges are all covered with veneer edge banding, which you can buy from most home stores or online.

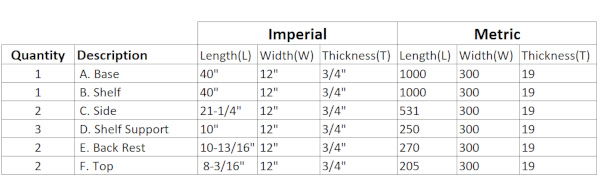

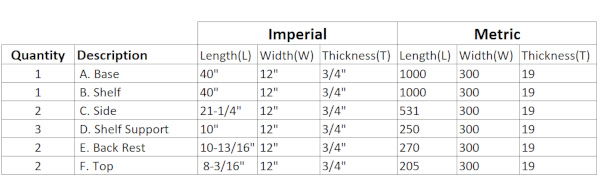

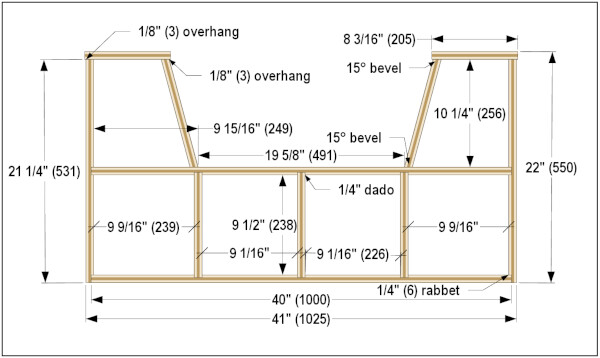

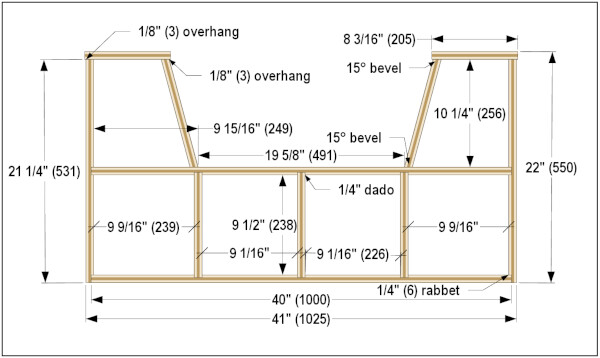

Cutting List

Dimensions – Pieces

Dimensions – Assembled

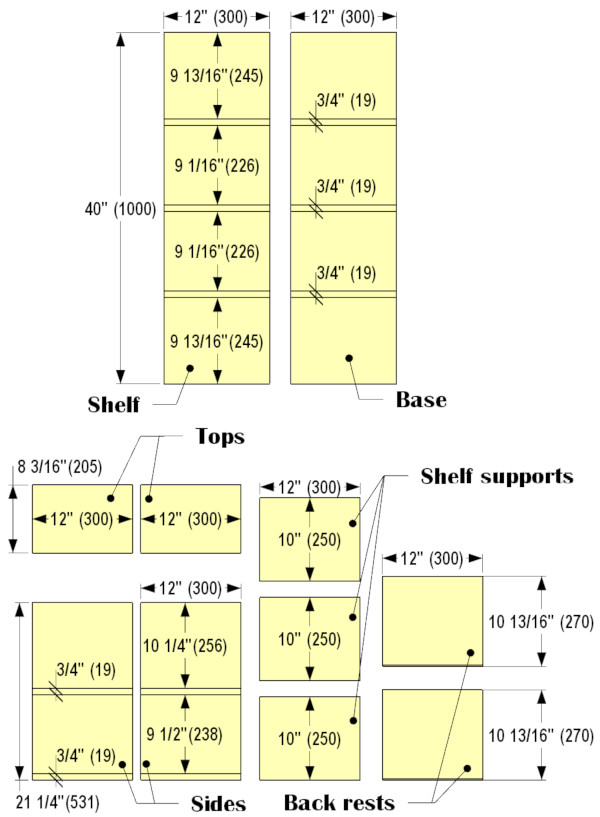

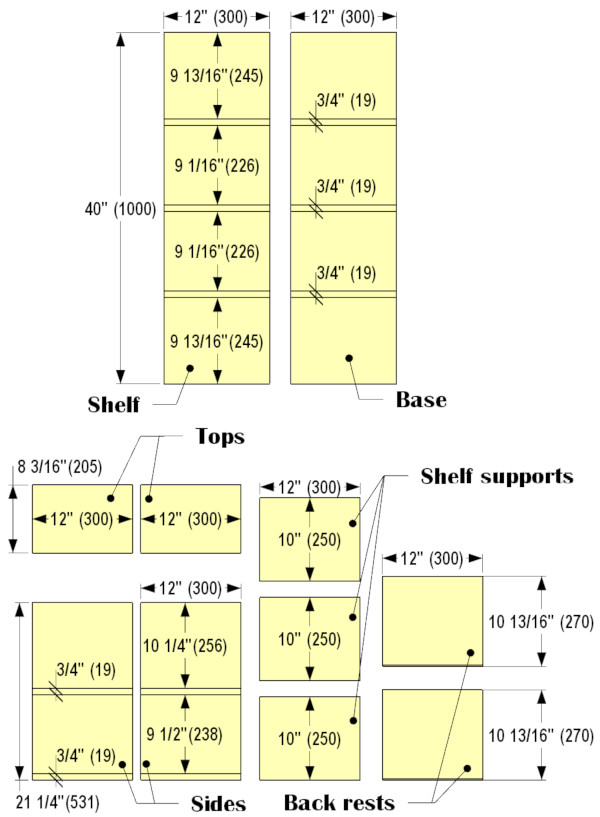

Refer to diagrams above to cut your pieces and make your dados and rabbets.

The back rests (E) will need a 15 degree bevel cut at the top and bottom of each.

Related:

- Dados, Grooves and Rabbets Explained

- Plywood 101

- Working with Plywood

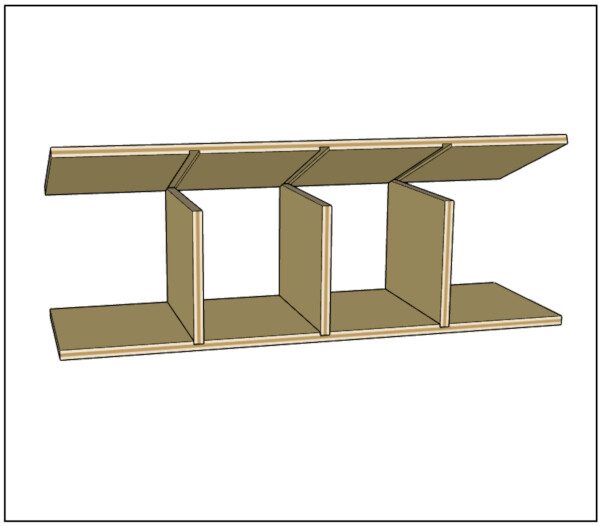

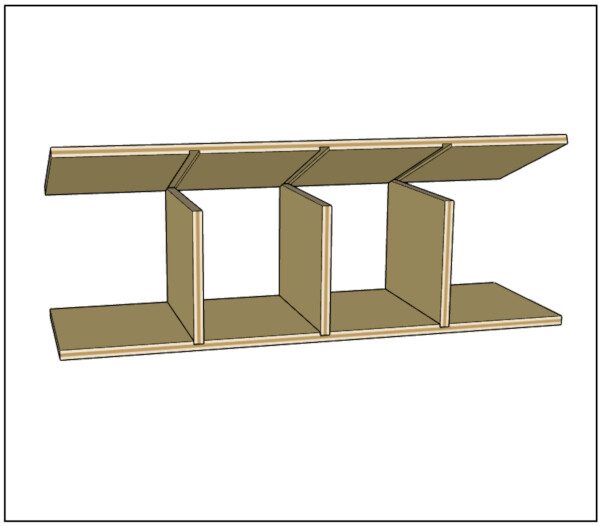

STEP 1

Cut 3/4″ dados in the base and the shelf, 1/4″ deep. Glue the shelf supports, base, and shelf together as shown here.

Optional – reinforce dado/glue joints with brad nails. See Appendix A below.

Step 2

Drill pocket holes, and cut 3/4″ dados and rabbets in each side piece as shown here. Glue each side to the edges of the base and shelf.

Optional – reinforce dado/glue joints with brad nails. See Appendix A below.

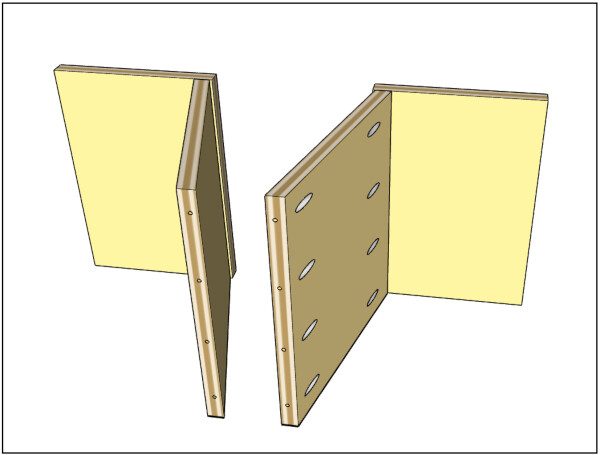

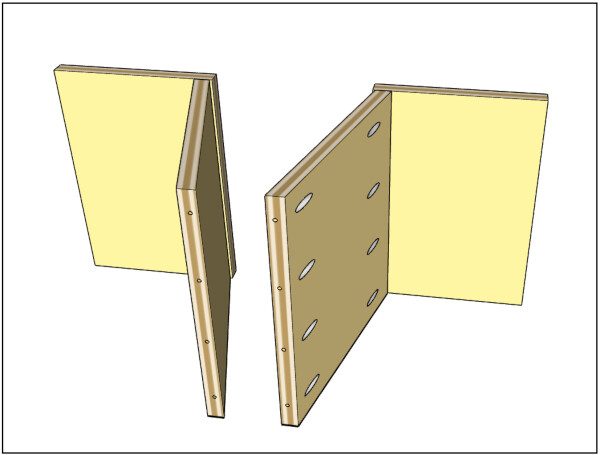

Step 3

Drill pocket holes in the Back Rest pieces as shown, and then attach each back rest to a Top Piece. Use glue and pocket screws.

Optional – fill pocket holes with plugs and sand smooth.

Step 4

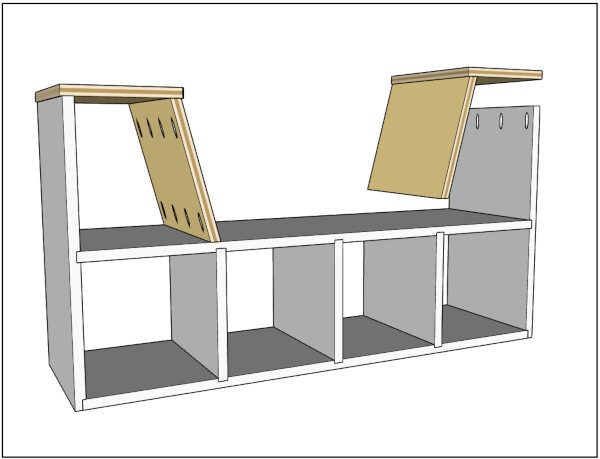

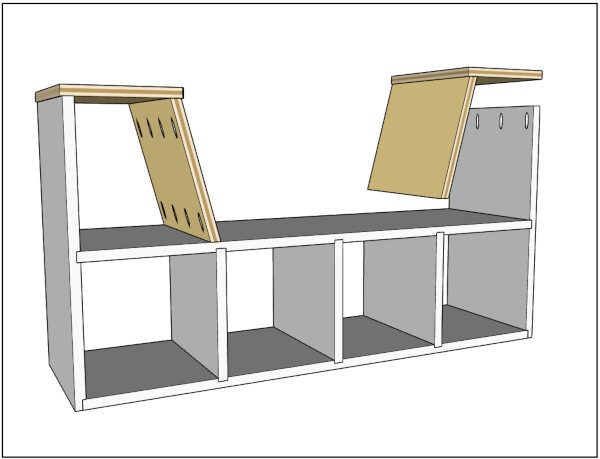

Attach the assembly from step 3 to the shelf and sides as shown here. Use glue and pocket screws.

Optional – fill pocket holes with plugs and sand smooth.

Step 5

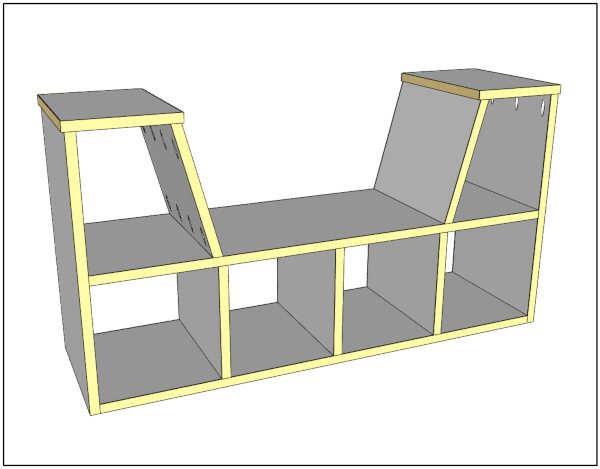

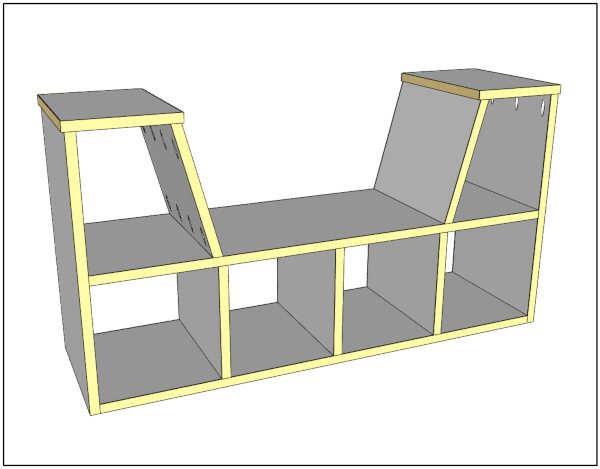

Apply your veneer edge banding around the exposed edges of all your plywood as shown below.

Related: 7 Steps To Edge Banding Plywood

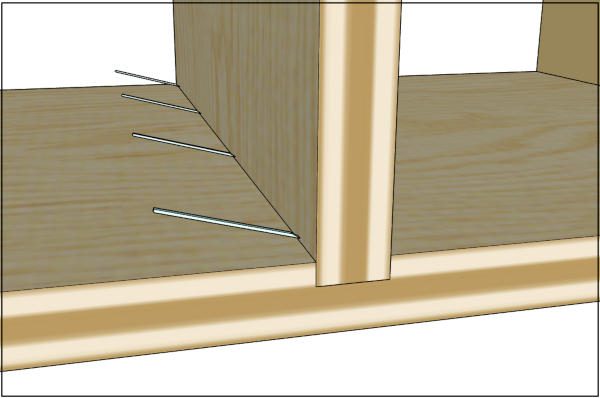

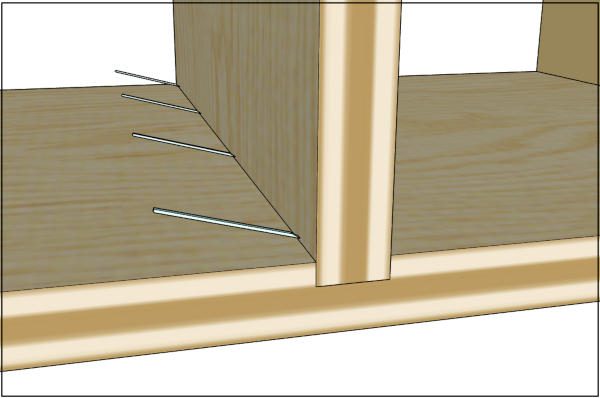

Appendix A

Reinforcing Dados with Brad Nails

Using a brad nailer, insert 1-1/2″ brads into the face of the work piece at the angle shown here. (This does not replace the glue, it reinforces it)

Subscribe below for a printable PDF version of these plans.

Related:

Handling and Breaking Down Plywood

Edge Banding Plywood