In the times we live in, efficiency is key. To offset the rising costs of goods, services, and energy we must be purposeful in lowering costs wherever we can. Every company has large utility expenses such as electricity, water, gas, sewer, waste, and recycling. Many companies have policies and systems in place to help control these expenses. One major utility that gets overlooked is your compressed air. Many companies just loop this expense into the gas and or electricity funnel and move on. But that can be a costly mistake. Assuming you utilize compressed air in your facility, it is most likely your 3rd-4th highest utility expense. The good news is there are many ways to make this utility much more efficient.

We have several EXAIR blogs on how to improve your compressed air efficiency from mitigating leaks, sizing pipe properly, flow control, pressure regulators, engineered nozzles and tools, and even receiver tanks. These are all very effective ways to reduce this expense. There is another tool that I would like to share with you; our Digital Flow Meters. What they are, how they work, and how they can save you money…

With a rough cost of $0.25 per 1000 SCFM, wouldn’t it be nice to know how many SCFM you are using? (Please click here for a great blog on how to calculate your SCFM cost) More importantly how much air are you wasting… Your compressor information already tells you how much air it is producing and with EXAIR’s Digital Flowmeter, you will know the exact amount of compressed air that is being used, making it very easy to identify loss. These losses are primarily found in leaks or inefficient air products. A best practice is to install one of these on each leg of the air distribution system and monitor and and benchmark the compressed air usage.

The EXAIR Flowmeters work by measuring the temperature differential between two probes that are inserted into the compressed air pipes. One probe is kept warmer than the other, and the mass flow rate is determined by the amount of heat required to maintain the temperature differential. The flow rate, or SCFM is displayed on the large digital display

To install the Flowmeters, you will drill 2 holes into your pipe for the probes. Included with the meter is the drill bit and the Drill Guide to quickly install the meter. We have these available in many sizes from 1/2″ to 4″ iron pipe, We also offer these for Copper Pipes, and can make / calibrate them for many others, we will just need the information.

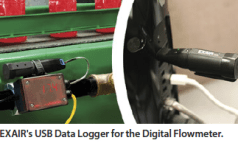

In addition to our standard version we offer several upgrades. One is a Data Logging version. You can download our software and then set the data logging to record from once a second for about 9 hours of data to twice a day for over 2 years worth of data. You simply plug the Data Log Stick this into your computer, download and repeat.

We also offer a wireless option that will run through a ZigBee mesh Network. A radio module within each meter transmits data to an ethernet connected gateway. You can also piggyback meter to meter to extend the range for this wireless solution. Each meter has a range of about 100 feet.

Many people ask if they have to shut down their system to install the Flowmeters. Understanding that this could cause systemic issues, we have a Hot Tap option that will allow you to install while the pipe is still under pressure. It incorporates 2 valves that the probes pass through as well as a muffler that collects the chips from the drilling process. This is only available on the 2″ or larger units.

Speaking of pressure, we also offer a Pressure Sensing Digital flow meter. On this, there is a pressure sensor that is mounted between the two flow sensor probes. The pressure is sent via a second milliamp output. The display can be configured to show either pressure or flow. You can set this to send alarms if the pressure falls under 50 psi. Also only available on 2″ pipes and above.

Finally, we also offer Block Off Rings. These are simply rings to block off holes where the flowmeter was, in case you need to use the same one in a different location.

Please fee free to reach out with any questions, or for more information. Let us help you save air and money…

Thank you for stopping by,

Brian Wages

Application Engineer

EXAIR Corporation

Visit us on the Web

Follow me on Twitter