In the world of industrial machinery, ensuring that equipment runs smoothly and efficiently is paramount. Progressive cavity pumps, known for their ability to handle a wide range of fluids, are commonly used in various industries. However, like any piece of machinery, they require maintenance and occasional replacement of parts. One question that often arises is whether investing in Original Equipment Manufacturer (OEM) spare parts for progressive cavity pumps is worth the cost. This article explores the benefits and considerations of using OEM spare parts.

Understanding Progressive Cavity Pumps

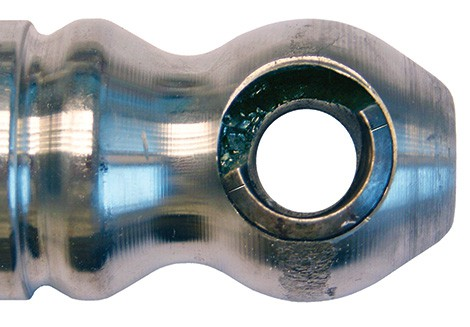

Progressive cavity pumps operate using a helical rotor that turns within a stator, creating cavities that move fluid through the pump. This design allows for a consistent flow rate and makes them suitable for handling viscous materials, slurries, and even shear-sensitive fluids. Given their critical role in many operations, maintaining these pumps in optimal condition is essential.

The Case for OEM Spare Parts

Quality Assurance

One of the primary advantages of choosing OEM spare parts is the assurance of quality. OEM parts are specifically designed and manufactured to meet the exact specifications of the original machinery. This means that they are made from high-quality materials and undergo stringent testing to ensure reliability and performance. In contrast, aftermarket parts may vary in quality, potentially leading to premature wear and tear.

Compatibility

When replacing a part in a progressive cavity pump, compatibility is crucial. OEM spare parts are designed to fit perfectly with the existing machinery, ensuring seamless integration. This reduces the risk of malfunctions or inefficiencies that can arise from using ill-fitting aftermarket components. Proper compatibility contributes to the overall longevity of the equipment.

Enhanced Performance

Using OEM spare parts can significantly enhance the performance of progressive cavity pumps. These parts are engineered to work in harmony with the pump’s design, resulting in improved efficiency and reliability. When all components are functioning optimally, businesses can expect fewer disruptions in their operations, leading to increased productivity.

Cost Considerations

Initial Investment vs. Long-Term Savings

While OEM spare parts may come with a higher initial cost compared to aftermarket alternatives, it is essential to consider the long-term savings they can provide. The durability and reliability of OEM parts often translate to lower maintenance costs and reduced downtime. In many cases, the investment in OEM parts pays off over time through enhanced performance and fewer repairs.

Warranty and Support

Another factor to consider is the warranty and support that come with OEM spare parts. Manufacturers typically offer warranties that cover defects and performance issues, providing peace of mind for businesses. In addition, OEM suppliers often provide technical support and resources to help with installation and troubleshooting, further ensuring that operations run smoothly.

Potential Drawbacks

Higher Initial Costs

Despite the numerous benefits, the higher initial cost of OEM spare parts can be a drawback for some businesses, especially smaller operations with limited budgets. It’s essential for companies to weigh the costs against the potential long-term benefits to make an informed decision.

Limited Options

Another consideration is the limited options available with OEM parts compared to aftermarket alternatives. Some businesses may prefer the flexibility and variety offered by aftermarket suppliers. However, it’s crucial to prioritize quality and compatibility when choosing replacement parts.

Making the Right Choice

When deciding whether to invest in progressive cavity OEM spare parts, businesses should consider several factors:

- Operational Needs: Assess the criticality of the pump in your operations. For mission-critical applications, the reliability of OEM parts may outweigh the cost.

- Budget Constraints: Evaluate your budget and determine if the long-term savings from OEM parts align with your financial goals.

- Maintenance Strategy: Consider your overall maintenance strategy. If you prioritize reliability and performance, OEM parts are likely the better choice.

Conclusion

Investing in progressive cavity OEM spare parts can be a worthwhile decision for many businesses. The quality, compatibility, and enhanced performance they offer often justify the higher initial investment. While there are valid considerations regarding cost and options, the long-term benefits of using OEM parts can lead to improved efficiency, reduced downtime, and ultimately, greater profitability. By carefully evaluating your specific needs and circumstances, you can make an informed decision that supports the longevity and reliability of your progressive cavity pumps.