EXAIR manufactures Cabinet Coolers to keep your electrical components cool inside. This will help to prevent any costly shutdowns or premature electrical failures due to overheating. The EXAIR Cabinet Cooler System is a simple device that generates cold air with no moving parts, motors, condensers, or Freon. They are maintenance-free with a long-life cycle, and installation is quick and easy. But when mounting the system to your electrical panel, you want to make sure that the Cabinet Cooler meets or exceeds the integrity standard for that environment. There are standards that categorize electrical panels to protect workers, shield the panel from the environment, and sustain the internal electrical components.

Electrical panels come in all shapes, sizes, and colors and can be used in a variety of environments, including indoor, outdoor, and even hazardous locations. Depending on the place and setting, you will need to determine the minimum requirements for the integrity of your electrical panel. For example, you do not want to use an “indoor only” electrical enclosure for outside areas. Also, you would not want a standard enclosure to be used in a hazardous area, as it can be very dangerous. The major organizations that create these electrical standards are NEMA, UL, and IP. In this blog, I will cover these organizations and how they use the rating system.

NEMA, or National Electrical Manufacturer Association, and UL, or Underwriters Laboratory, are generally used in North America. The difference between these two organizations is that the NEMA ratings are self-certifying, while the UL requires testing by qualified inspectors, independent of the manufacturer, for compliance. They use numbers and, in some instances, letters to indicate the type of environment in which the enclosure can operate. EXAIR Cabinet Cooler Systems are UL listed, so they have been tested and verified. Currently, there are over 20 different NEMA/UL classifications.

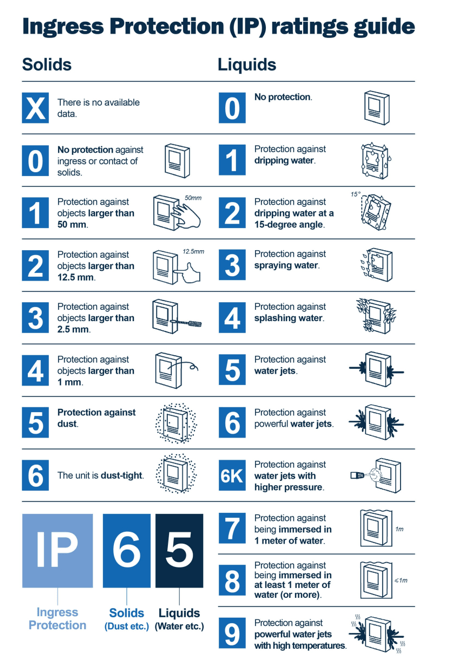

IP, or Ingress Protection, is an international standard commonly used in Europe and established by the International Electrotechnical Commission, or IEC. This organization also allows for self-certification. They use two digits to define levels of integrity for electrical enclosures against intrusion from debris and liquid. The first digit ranges from 0 to 6, which specifies the protection rating from solids. The second digit, which ranges from 0 to 9, specifies the protection rating for the ingress of water. The higher the number, the better the protection. The combination of these two numbers will determine the protection level of the enclosure against dust and water. There is an equivalence between the NEMA ratings and the IP ratings, but it is up to the preference of the user to verify the protection requirement.

EXAIR offers three main NEMA types for our Cabinet Cooler Systems, which are the most commonly found within most facilities. We also offer two additional NEMA ratings that are designated strictly for hazardous locations: UL Classified and ATEX rated.

NEMA 12 (IP54) Cabinet Coolers are rated for dust and oil tight. NEMA 12 cabinet coolers are ideal for general industrial environments where no liquids or corrosives are present and are located inside the facility.

NEMA 4 (IP66) Cabinet Coolers are rated for dust tight, oil tight, splash-resistant and indoor/outdoor service. These Cabinet Coolers incorporate a low-pressure relief valve to allow the internal hot air to escape as well as to close and seal when the cooler is not in operation. This allows this Cabinet Cooler to maintain the integrity of a NEMA 4 enclosure.

NEMA 4X (IP66) Cabinet Coolers offer the same protection as NEMA 4 but are constructed of stainless steel for food service and corrosive environments. EXAIR offers both 303SS and 316SS materials.

HazLoc Cabinet Coolers are designed for hazardous locations and are mounted to NEMA 7, 8, and 9 enclosures. EXAIR catalogs these Cabinet Coolers as NEMA 4 (IP66) or NEMA 4X (IP66), as mentioned above. But their registration for UL classified is for Class I, Class II, and Class III hazardous areas, both Div 1 and Div 2. The reason that they do not match the NEMA rating of the hazardous panels is because they require an X-type or Z-type purge system. In combination, they will not sacrifice the integrity of the hazardous electrical panels.

ATEX Cabinet Coolers have similar attributes as HazLoc Cabinet Coolers except this type of registration is popularly used in Europe. These area classifications fall under the EN/IEC 60079-2 international standard for explosive zones. It covers three zones in two hazardous areas, gas/liquid and dust. The ATEX Cabinet Coolers can be used in Zone 2 for gas/liquid and Zone 22 for dust. Like the HazLoc Cabinet Coolers, to keep their classification, the ATEX Cabinet Coolers require a Zone 2/22 purge system. The ATEX terminology is as follows:

Gas – CE EX II 3 G Ex h IIC T3 Gc

Dust – CE EX II 3 D Ex h IIIC 200oC Dc

EXAIR offers a variety of Cabinet Coolers in stock with different cooling capacities, materials of construction, and operational locations. We also offer them in 316SS, high temperature versions, and non-hazardous purge. We do have a Cabinet Cooler System Sizing Guide to help determine the best product for your application or a Cabinet Cooler System Calculator to do it yourself. For any hazardous location, we do recommend contacting us for clarification. If you have any questions, an Application Engineer at EXAIR can assist you.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb