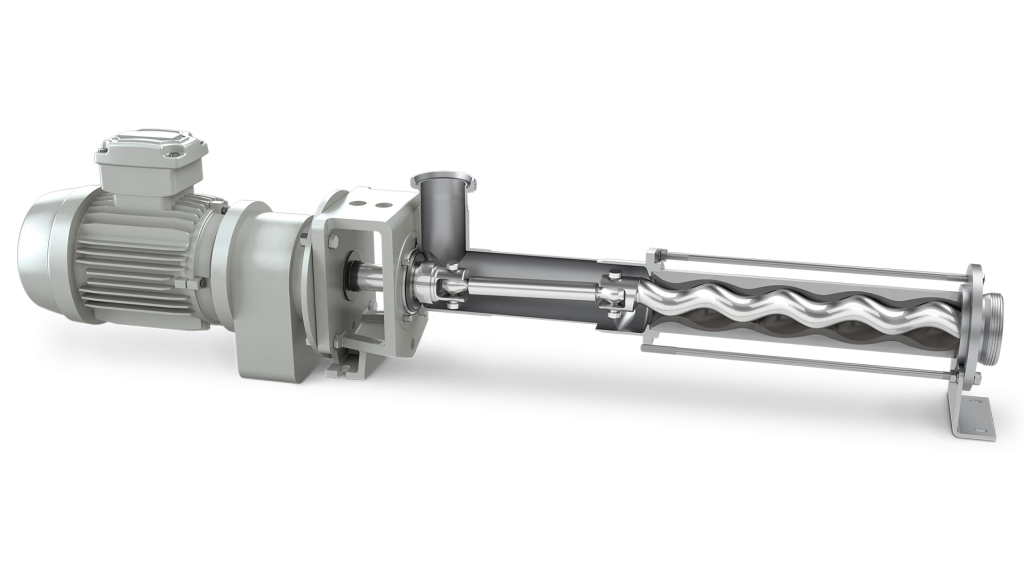

The Netzsch NEMO pump is a progressive cavity pump renowned for its reliability and efficiency in a wide range of applications. To ensure optimal performance and service life, regular maintenance is essential. This article outlines the main requirements of the Netzsch NEMO pump maintenance manual.

Routine Inspection

Regular inspections are crucial to identify potential issues before they escalate. During these inspections, consider the following:

- Visual Check: Look for any signs of leaks or wear on the pump body and connections.

- Performance Monitoring: Observe the pump’s operational parameters, such as flow rate and pressure.

- Noise Assessment: Listen for unusual sounds that may indicate mechanical problems.

Lubrication

Proper lubrication is vital for the smooth operation of the pump’s components. The following points should be addressed:

- Lubrication Schedule: Establish a regular lubrication schedule based on the manufacturer’s recommendations.

- Type of Lubricant: Use the appropriate lubricant specified for the NEMO Pump to prevent damage.

- Check Levels: Regularly check lubricant levels and top up as necessary to avoid friction and wear.

Seals and Gaskets

Seals and gaskets play a crucial role in preventing leaks and maintaining pressure. Maintenance tasks include:

- Inspection: Regularly inspect seals and gaskets for signs of wear or damage.

- Replacement: Replace any worn or damaged seals promptly to maintain efficiency and prevent leaks.

Cleaning

Keeping the pump clean is essential for its performance. Maintenance should include:

- External Cleaning: Regularly clean the exterior of the pump to remove dust and debris.

- Internal Cleaning: Depending on the application, consider periodic internal cleaning to prevent the buildup of materials that could affect operation.

System Checks

The entire pumping system should be routinely checked to ensure compatibility and efficiency. Key aspects include:

- Piping Inspection: Examine the piping for blockages, corrosion, or other issues that may affect performance.

- Valves and Fittings: Check all valves and fittings for leaks and proper operation.

- Pressure Relief Valves: Ensure pressure relief valves are functioning correctly to prevent overpressure situations.

Documentation and Record Keeping

Maintaining accurate records is critical for effective maintenance management. This includes:

- Maintenance Logs: Keep a log of all inspections, repairs, and maintenance performed on the pump.

- Performance Records: Document performance metrics to establish baseline data and identify trends over time.

Conclusion

Regular maintenance of the Netzsch NEMO Pump is essential for ensuring its longevity and efficiency. By adhering to a structured maintenance plan that includes routine inspections, proper lubrication, seal checks, cleaning, system checks, and thorough documentation, operators can maximize the pump’s performance and reliability. Investing time in maintenance not only enhances the pump’s lifespan but also reduces the risk of unexpected failures, leading to smoother operations.