Bolt Pretightening Tutorial

What is tighten the torque

In principle, there are two tightening methods: “uncontrolled” and “controlled”.

Controlled tightening: the use of calibrated measurable equipment, in accordance with pre-specified methods, by trained personnel.

Uncontrolled tightening: use equipment or methods that cannot be measured.Apply pre-tightening to bolt and nut assemblies using a hammer and wrench or other type of punching tool

Advantages of controlled tightening

1. Known, controllable and accurate bolt load.The output controllable tool is used to calculate the required tool setting value.

2. Even bolt loading.This is especially important in joints with sealing gaskets, since uniform compression is required to make the gaskets effective.

3. Operate safely as scheduled.The dangerous action of manual non-controlled tightening is eliminated and the operators are required to be skilled and follow the prescribed methods.

4. Shorten operation time and improve productivity.Use controlled tools instead of manual labor to shorten tightening time and operator labor intensity.

5. Reliable and repeatable results.Use calibrated and tested equipment, follow prescribed methods, skilled operators, and consistently achieve known results.Get the right results at once.Many uncertainties of bolt failure in operation are eliminated by ensuring correct assembly and tightening of bolts.

Tighten the torque

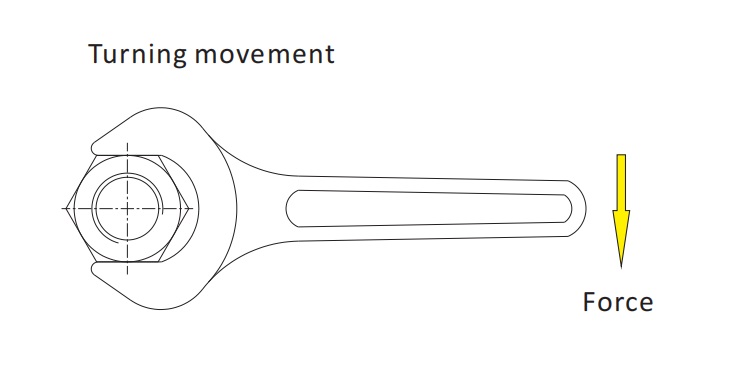

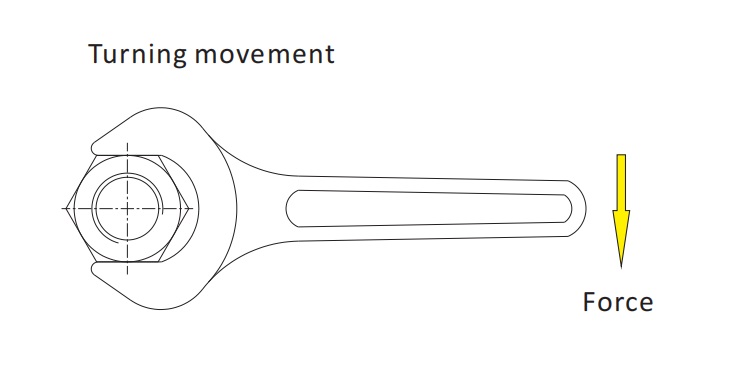

1. What is torque?

Torque is a measure of the amount of force acting on an object to make it rotate.

2. What is torque tightening?

Apply a preload on the fastener by rotating the nut of the fastener.

3. Tighten torque and preload

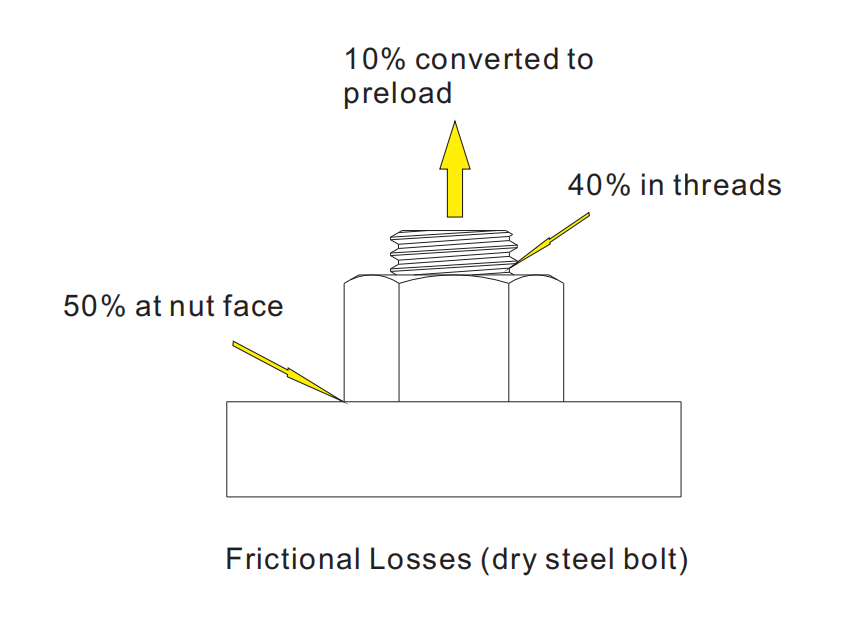

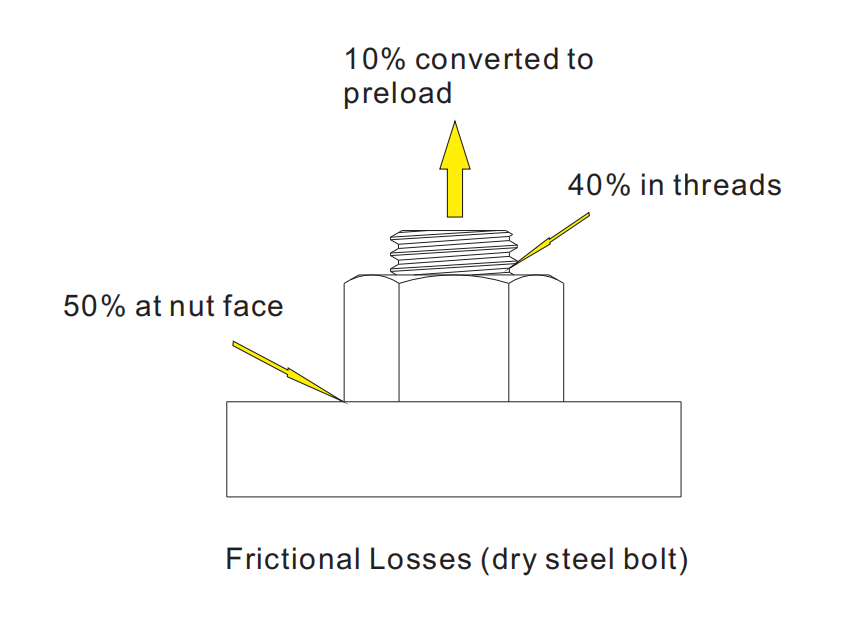

The amount of preload produced when torque is applied depends largely on friction.

4. There are mainly three different “torque components”

4.1 torque of elongated bolts

4.2 torque to overcome friction in bolt and nut threads

4.3 torque to overcome the friction at the bearing plane of the nut hole

Lubrication reduces friction

Lubrication during tightening reduces friction, reduces bolt failure during installation, and extends bolt life.The change of friction coefficient can affect the amount of preload achieved under the specified torque.

The higher the friction, the less torque is converted to preload. To accurately achieve the required torque value, the friction coefficient provided by the lubricant manufacturer must be known.Lubricants should be applied to nut bearing surfaces and threads.

Torque tightening

Frictional Losses

Torque fastening

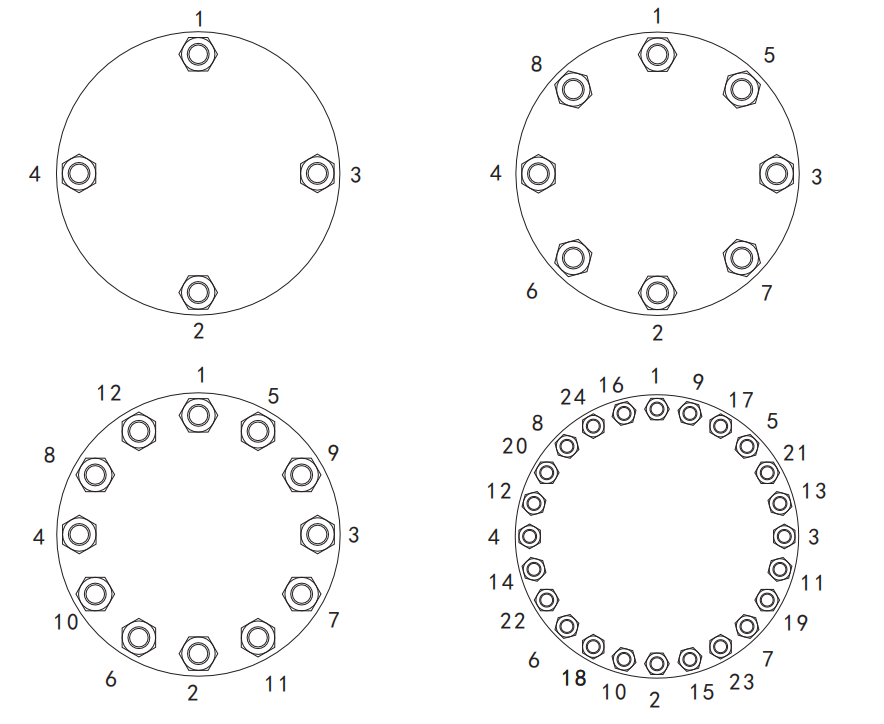

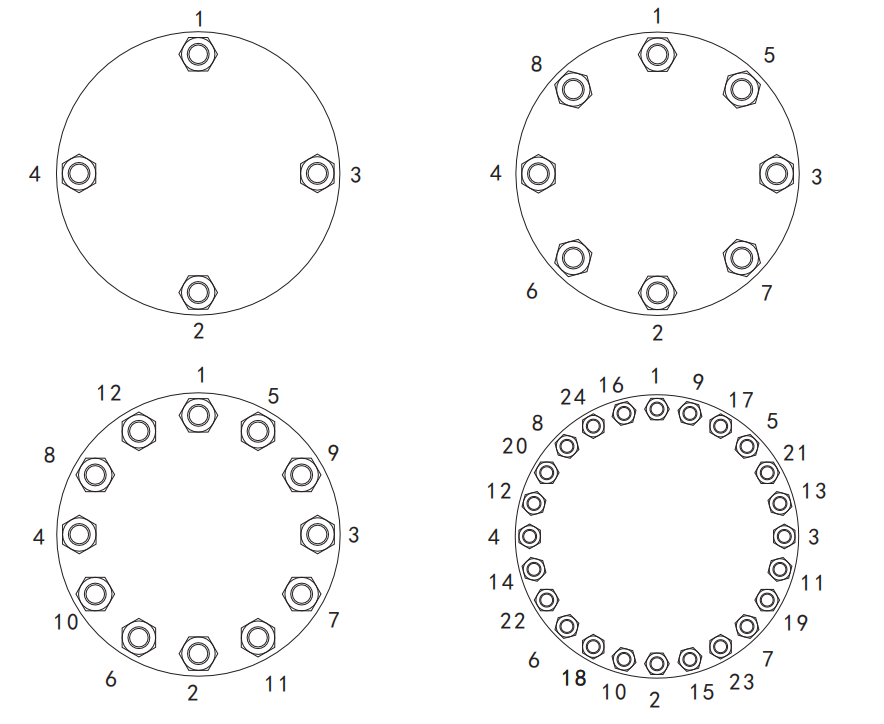

When tightening, you can usually tighten only one bolt at a time, which can lead to point loading and load dispersion.In order to prevent this from happening, torque should be applied step by step in accordance with the prescribed mode.

Load order

Step 1: tighten the nut quickly with a wrench to ensure 2-3 circles of thread sticking out the nut.

Part 2: tighten each bolt to 1/3 of the final torque in the mode shown above.

Part 3: tighten each bolt to 2/3 of the final required torque in the mode shown above.

Part 4: increase to full torque in the mode shown above.

Step 5: starting with bolt no. 1, tighten each bolt clockwise for the last time with the final torque value.

Select the correct torque wrench

1. When loosening nuts or bolts, the required torque is often greater than that of tightening

2. In general, it is required to apply a torque value of 2.5 times to remove nuts or bolts

3. When loosening nuts or bolts, the applied torque value shall not exceed 75% of the maximum torque of the tool

Note:Unscrew torque should be at least 2 times of tightening torque

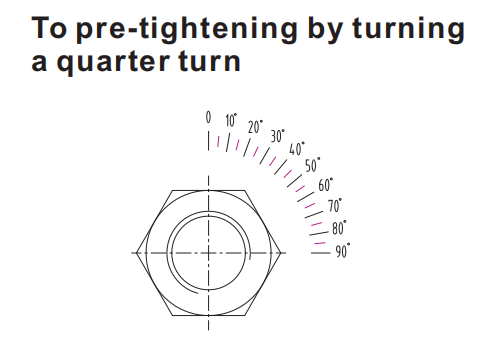

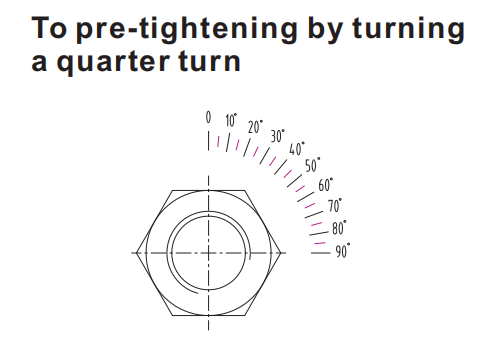

Torque corner fastening

Torque corner fastening is more accurate than torque fastening only

The precise pre-tightening force is achieved naturally with the defined turning Angle

High fastening quality

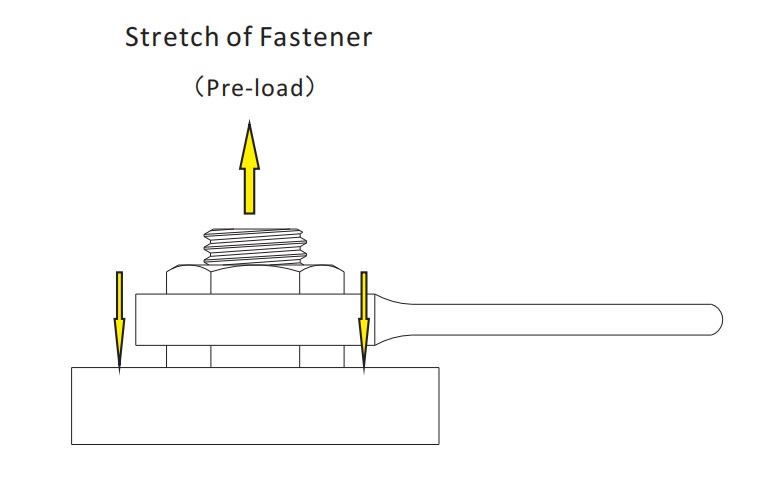

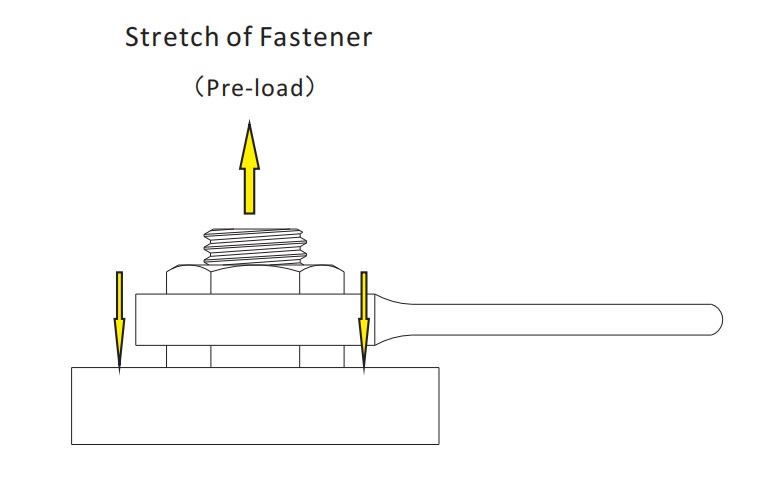

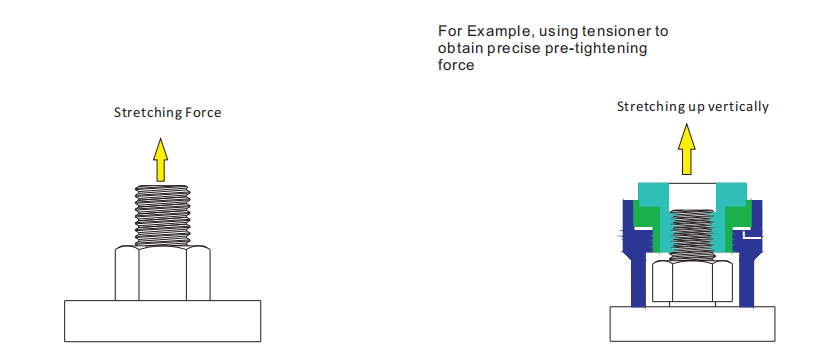

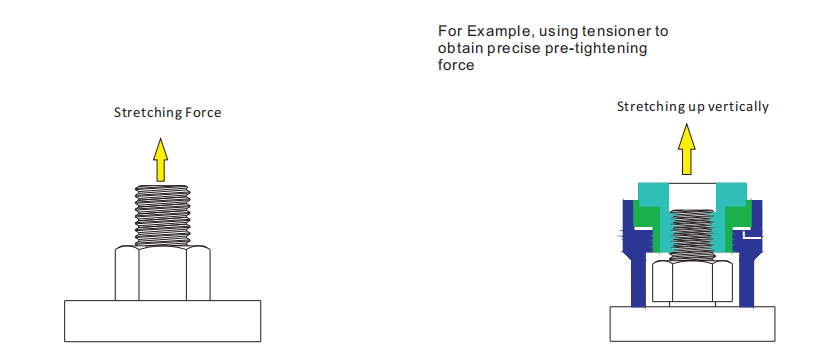

Tensile tightening

Condition for choosing tensile tightening

The stretching out length of the bolt from the nut have to be up to 1 time of the bolt diameter

Advantages of using tensile pre-tightening

Bolt is not twisted, therefore there is no torque force on the bolt

The precise torque achieved after tensile pre-tightening the nut

Conversion of Frequent Unit

Torque

1N.m=0.737Ft.lb

1Ft.lb=1.356N.m

1kg.m=7.233Ft.lb=9.8N.m

Length

1mm=0.039in

1in=25.4mm

1m=3.281Ft

1Ft=0.305m

Force

1kg=2.2046 lbs

1lbs=0.4536kg

1Ton=1000kg

1KN=0.102Ton

1Ton=9.81KN

Pressure

1MPa=1N/mm2

MPa=10.2kg/cm2

1MPa=10Bar

1MPa=145psi

1Bar=14.5psi

1psi=0.069Bar

Power

1Hp=0.746KW

1KW=1.34Hp

Weight

1Ton=9.8KN

1KN=0.102Ton

1N=0.102kg

1kg=9.8N

1kg=2.204 lb =9.8N